samfurori

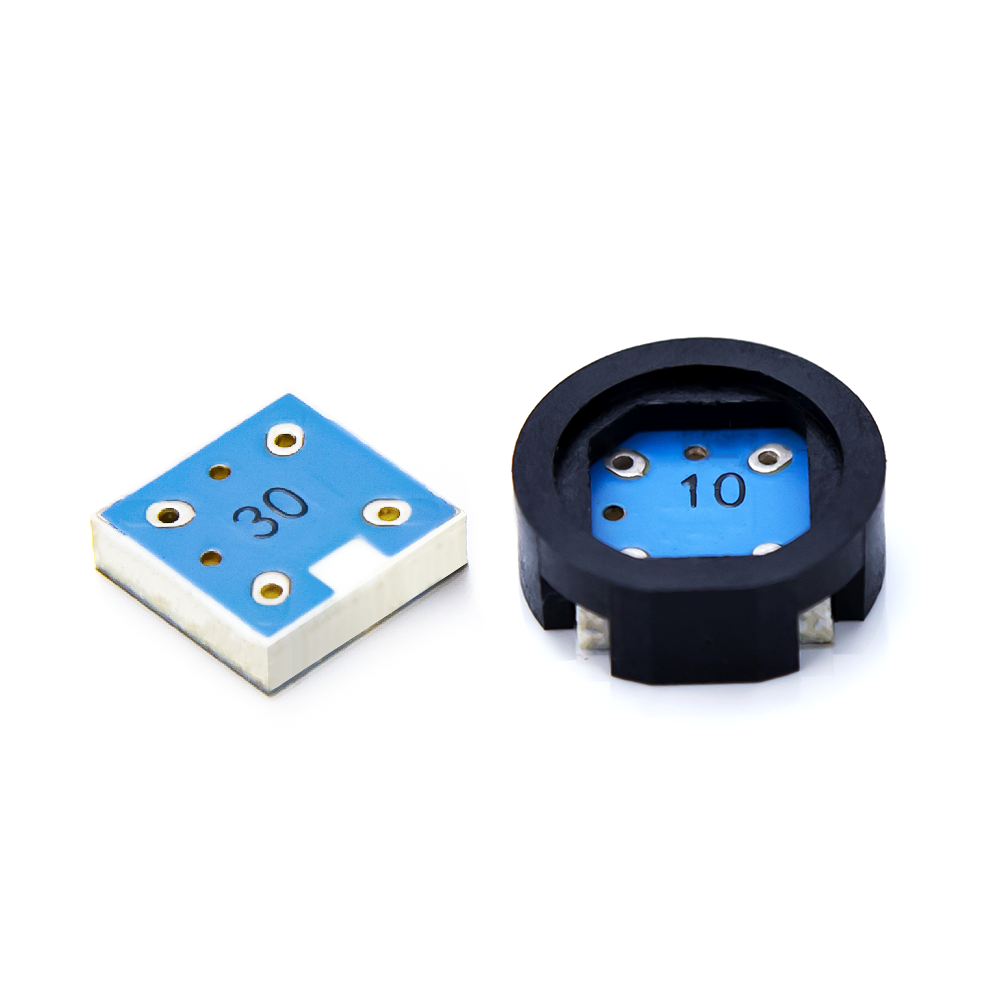

XDB100 Piezoresistive Monolithic Ceramic Pressure firikwensin

Siffofin

● Kyakkyawan kwanciyar hankali na dogon lokaci

● Matsakaicin ramuwa na zafin jiki

Aikace-aikace na yau da kullun

● Masana'antu

● Valve, watsawa, sinadarai, injiniyan petrochemical, ma'aunin asibiti da dai sauransu.

Ma'aunin Fasaha

| Kewayon matsin lamba | | Girma | φ (18/13.5)× (6.35/3.5) mm |

| Fashe matsa lamba | 1.15 ~ 3 sau (jeri sun bambanta) | Ƙarfin wutar lantarki | 0-30 VDC (max) |

| Gada impedance | | Cikakken fitarwa | ≥2 mV/V |

| Yanayin aiki | -40 ~ + 135 ℃ | Yanayin ajiya | -50 ~ + 150 ℃ |

| Gabaɗaya daidaito (mai layi + hysteresis) | ≤± 0.3% FS | Juyin yanayin zafi (sifili & hankali) | ≤± 0.03% FS/℃ |

| Dogon kwanciyar hankali | ≤± 0.2% FS / shekara | Maimaituwa | ≤± 0.2% FS |

| Sifili diyya | ≤± 0.2 mV/V | Juriya na rufi | ≥2 KV |

| Tsawon lokaci mai tsawo @20°C | ± 0.25% FS | Dangi zafi | 0 ~ 99% |

| Sadarwa kai tsaye tare da kayan ruwa | 96% Al2O3 | Cikakken nauyi | ≤7g (misali) |

Bayanan kula

1. Lokacin shigar da jigon firikwensin yumbu, yana da mahimmanci a mayar da hankali kan shigarwa na dakatarwa. Tsarin ya kamata ya haɗa da ƙayyadaddun zobe na matsa lamba don iyakance matsayi na mahimmancin firikwensin kuma tabbatar da ko da rarraba damuwa. Wannan yana taimakawa wajen guje wa bambance-bambance a cikin matsananciyar damuwa wanda zai iya haifar da ma'aikata daban-daban.

2. Kafin waldawa, yi duban gani na kushin firikwensin. Idan oxidation ya kasance a saman kushin (yana juya shi duhu), tsaftace kushin tare da gogewa kafin waldawa. Rashin yin hakan na iya haifar da rashin kyawun fitowar sigina.

3. Lokacin walda wayoyi na gubar, yi amfani da tebur mai dumama tare da sarrafa zafin jiki wanda aka saita a digiri 140-150. Ya kamata a sarrafa baƙin ƙarfe a kusan digiri 400. Za'a iya amfani da tushen ruwa, juzu'i mara wankewa don allurar walda, yayin da ana ba da shawarar manna mai tsabta don wayar walda. Ya kamata mahaɗin mai siyarwa ya zama santsi kuma babu burrs. Rage lokacin hulɗa tsakanin baƙin ƙarfe da kushin, kuma guje wa barin iron ɗin a kan kushin firikwensin fiye da daƙiƙa 30.

4. Bayan walda, idan ya cancanta, tsaftace saura juzu'i tsakanin wuraren waldawa ta amfani da ƙaramin goga tare da cakuda 0.3 sassa cikakkar ethanol da 0.7 sassa na kewaye allo. Wannan matakin yana taimakawa hana saura juyi daga samar da karfin parasitic saboda danshi, wanda zai iya shafar daidaiton siginar fitarwa.

5. Gudanar da gano siginar fitarwa akan firikwensin welded, tabbatar da ingantaccen siginar fitarwa. Idan tsalle-tsalle na bayanai ya faru, dole ne a sake haɗa firikwensin kuma a haɗa shi bayan wucewar ganowa.

6. Kafin yin amfani da firikwensin firikwensin bayan taro, yana da mahimmanci don ƙaddamar da abubuwan da aka haɗa don damuwa don daidaita ma'auni na taro kafin ƙaddamar da sigina.

Yawanci, ana iya amfani da hawan keke mai tsayi da ƙananan zafin jiki don haɓaka ma'auni na damuwa bayan tsarin haɓakawa da ƙaddamarwa. Ana iya samun wannan ta hanyar ƙaddamar da abubuwan da aka gyara zuwa kewayon zafin jiki na -20 ℃ zuwa 80-100 ℃ ko zazzabi na dakin zuwa 80-100 ℃. Lokacin rufewa a maɗaukaki da ƙananan zafin jiki ya kamata ya zama mafi ƙarancin sa'o'i 4 don tabbatar da sakamako mafi kyau. Idan lokacin rufewa ya yi tsayi sosai, za a lalata tasirin aikin. Za'a iya ƙayyade ƙayyadadden yanayin zafin tsari da lokacin rufewa ta hanyar gwaji.

7. Ka guje wa tatsar diaphragm don hana yuwuwar lalacewar da'irar ciki na cibiyar firikwensin yumbu, wanda zai iya haifar da rashin kwanciyar hankali.

8. Yi taka tsantsan yayin hawa don hana duk wani tasiri na inji wanda zai iya haifar da rashin aiki na jigon ji.

Lura cewa shawarwarin da ke sama don taron firikwensin yumbu sun keɓanta ga tsarin tafiyar da kamfaninmu kuma maiyuwa ba lallai ba ne su zama ma'auni don ayyukan samar da abokin ciniki.

Bayanin oda