A cikin ma'aunin matsi, ƙila za ku lura cewa sakamakon ma'aunin ba ya nuna canje-canje nan da nan a cikin matsa lamba ko daidai daidai lokacin da matsa lamba ya koma matsayinsa na farko. Misali, lokacin amfani da ma'aunin gidan wanka don auna nauyi, firikwensin sikelin yana buƙatar lokaci don fahimtar daidai da daidaita karatun nauyin ku. Thelokacin amsawana firikwensin yana haifar da canjin bayanan farko. Da zarar firikwensin ya daidaita zuwa nauyi kuma ya kammala aikin sarrafa bayanai, karatun zai nuna ƙarin tabbataccen sakamako.Wannan ba lahani ba ne na firikwensin amma halayen na yau da kullun na na'urorin aunawa na lantarki da yawa, musamman lokacin da ya haɗa da sarrafa bayanai na lokaci-lokaci da ci gaba mai ƙarfi. Ana iya kiran wannan al'amari da hysteresis na firikwensin.

Menene hysteresis a cikin na'urori masu auna matsa lamba?

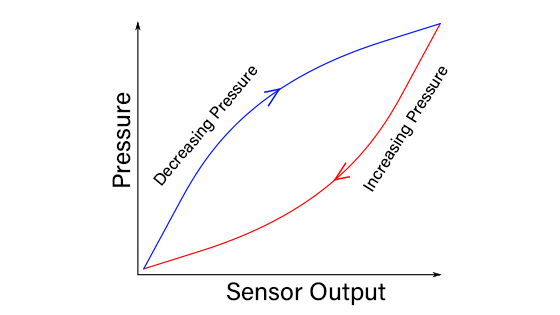

Sensorhysteresisyawanci yana bayyana lokacin da aka sami canjin shigarwa (kamar zafin jiki ko matsa lamba), kuma siginar fitarwa ba ya bin canjin shigar da sauri, ko kuma lokacin da shigarwar ta dawo yadda take, siginar fitarwa ba ta cika komawa yanayinta na farko ba. . Ana iya ganin wannan al'amari a kan siffa ta firikwensin, inda akwai lanƙwasa mai kama da madauki tsakanin shigarwa da fitarwa, maimakon layi madaidaiciya. Musamman, idan kun fara haɓaka shigarwar daga takamaiman ƙima, fitowar firikwensin kuma zai ƙaru daidai da haka. Duk da haka, lokacin da shigarwar ya fara raguwa zuwa ainihin ma'anar, za ku ga cewa ƙimar fitarwa ta fi girma fiye da ƙimar fitarwa na asali yayin aikin ragewa, samar da madauki komadauki hysteresis. Wannan yana nuna cewa yayin haɓakawa da raguwar tsari, ƙimar shigarwa iri ɗaya ta dace da ƙimar fitarwa daban-daban guda biyu, wanda shine nunin fahimta na hysteresis.

Hoton yana nuna alaƙar da ke tsakanin fitarwa da matsa lamba a cikin firikwensin matsa lamba yayin aiwatar da aikace-aikacen matsa lamba, wanda aka wakilta a cikin nau'in lanƙwasa hysteresis. Axis a kwance yana wakiltar fitowar firikwensin, kuma axis na tsaye yana wakiltar matsa lamba. Ƙunƙarar ja tana wakiltar tsari inda firikwensin firikwensin ya karu tare da ƙara matsa lamba a hankali, yana nuna hanyar amsawa daga ƙananan zuwa matsa lamba. Layin shuɗi yana nuna cewa yayin da matsa lamba ya fara raguwa, fitarwar firikwensin kuma yana raguwa, daga babban matsa lamba baya zuwa ƙasa, yana nuna yanayin firikwensin yayin sauke nauyin. Wurin da ke tsakanin maɓallan biyu, madauki na hysteresis, yana nuna bambanci a cikin fitarwa na firikwensin a matakin matsa lamba ɗaya yayin lodawa da saukewa, yawanci lalacewa ta hanyar kaddarorin jiki da tsarin ciki na kayan firikwensin.

Dalilan Matsalolin Hawan Jini

Alamar hysteresis a cikinna'urori masu auna matsa lambamanyan abubuwa guda biyu ne suka fi rinjaye su, waɗanda ke da alaƙa da kaddarorin jiki da tsarin aiki na firikwensin:

- Material's elastic hysteresis Duk wani abu zai fuskanci wani mataki na nakasawa na roba lokacin da aka sa shi ga sojojin waje, amsa kai tsaye na kayan ga sojojin da aka yi amfani da su. Lokacin da aka cire ƙarfin waje, kayan yana ƙoƙarin komawa zuwa asalinsa. Duk da haka, wannan farfadowa bai cika ba saboda rashin daidaituwa a cikin tsarin kayan ciki da kuma ƙananan canje-canjen da ba za a iya jurewa ba a cikin ƙananan ƙananan ƙwayoyin ciki a lokacin maimaitawa da saukewa. Wannan yana haifar da raguwar fitarwar halayen injina yayin ci gaba da ɗaukar nauyi da tafiyar matakai, wanda aka sani dana roba hysteresis. Wannan sabon abu ne musamman bayyananne a cikin aikace-aikace nana'urori masu auna matsa lamba, kamar yadda na'urori masu auna firikwensin sau da yawa suna buƙatar aunawa da amsa ga canjin matsa lamba daidai.

- Gogayya A cikin injina na na'urar firikwensin matsa lamba, musamman waɗanda suka shafi sassa masu motsi, gogayya ba makawa. Wannan gogayya na iya fitowa daga lambobi a cikin firikwensin, kamar madaidaicin wuraren sadarwa, bearings, da sauransu. Lokacin da firikwensin ya ɗauki matsin lamba, waɗannan wuraren juzu'in na iya hana motsi na injin firikwensin cikin kyauta, yana haifar da jinkiri tsakanin martanin firikwensin da ainihin matsi. Lokacin da aka sauke matsin lamba, ƙarfin juzu'i iri ɗaya na iya hana tsarin cikin gida tsayawa nan da nan, don haka kuma yana nuna jijiyoyi yayin lokacin saukewa.

Wadannan abubuwa guda biyu tare suna haifar da madauki na hysteresis da aka gani a cikin na'urori masu auna firikwensin yayin gwaje-gwaje masu maimaitawa da zazzagewa, yanayin da galibi yakan damu musamman a aikace-aikace inda ake buƙatar daidaito da maimaitawa sosai. Don rage tasirin wannan abin al'ajabi, ƙira a hankali da zaɓin kayan abu don firikwensin yana da mahimmanci, kuma ana iya buƙatar algorithms na software don rama wannan ƙarar a cikin aikace-aikace.

Alamar hysteresis a cikinna'urori masu auna matsa lambayana tasiri da abubuwa daban-daban kai tsaye masu alaƙa da halayen zahiri da sinadarai na firikwensin da yanayin aikin sa.

Wadanne abubuwa ne ke haifar da hysteresis na firikwensin?

1. Material Properties

- Module na roba: Ƙaƙwalwar kayan abu yana ƙayyade matakin nakasar roƙo lokacin da aka yi masa ƙarfi. Materials tare da mafi girma na roba modulus nakasa kasa, kuma suna roba hysteresiszai iya zama ƙasa kaɗan.

- Matsakaicin Poisson: Rabon Poisson yana kwatanta rabon ƙanƙancewa na gefe zuwa tsayin daka a cikin wani abu lokacin da aka yi masa ƙarfi, wanda kuma yana shafar halayen kayan yayin lodawa da saukewa.

- Tsarin ciki: ƙananan kayan aikin, gami da tsarin lu'ulu'u, lahani, da haɗe-haɗe, yana shafar halayen injinsa da halayen ɗabi'a.

2. Tsarin sarrafawa

- Machining machining: Madaidaicin kayan aikin firikwensin yana shafar aikin sa kai tsaye. Abubuwan da ke da madaidaicin madaidaici sun fi dacewa, rage ƙarin juzu'i da damuwa da damuwa da ke haifar da rashin dacewa.

- Ƙunƙarar saman: Ingancin jiyya na sama, kamar ƙanƙara, yana shafar girman juzu'i, ta haka yana rinjayar saurin amsawar firikwensin da ƙwanƙwasa.

- Canje-canjen yanayin zafi yana shafar kaddarorin zahiri na kayan, kamar na'urorin roba da juzu'i. Babban yanayin zafi gabaɗaya yana sa kayan su yi laushi, yana rage maɗaukakin roba da haɓaka juzu'i, ta haka yana ƙaruwa. Sabanin haka, ƙananan yanayin zafi na iya sa kayan su yi ƙarfi kuma sun fi karɓuwa, suna shafar hysteresis ta hanyoyi daban-daban.

3. Zazzabi

- Canje-canjen yanayin zafi yana shafar kaddarorin zahiri na kayan, kamar na'urorin roba da juzu'i. Babban yanayin zafi gabaɗaya yana sa kayan su yi laushi, yana rage maɗaukakin roba da haɓaka juzu'i, ta haka yana ƙaruwa. Sabanin haka, ƙananan yanayin zafi na iya sa kayan su yi ƙarfi kuma sun fi karɓuwa, suna shafar hysteresis ta hanyoyi daban-daban.

Hatsari

Kasancewar hysteresis a cikina'urori masu auna matsa lambana iya haifar da kurakuran ma'auni, yana shafar daidaito da amincin firikwensin. A cikin aikace-aikacen da ke buƙatar ma'auni masu mahimmanci, kamar daidaitaccen tsarin sarrafa masana'antu da kulawa da kayan aikin likita mai mahimmanci, hysteresis na iya haifar da kurakuran ma'auni mai mahimmanci kuma har ma ya sa tsarin ma'aunin duka ya kasa. Don haka, fahimta da rage tasirin hysteresis wani muhimmin sashi ne na tabbatar da ingantaccen aiki da ingantaccen aikina'urori masu auna matsa lamba.

Magani don Hysteresis a cikin Matsakaicin Sensors:

Don tabbatar da mafi ƙarancin yiwuwar tasirin hysteresis a cikina'urori masu auna matsa lamba, masana'antun sun ɗauki matakai masu mahimmanci don haɓaka aikin firikwensin:

- Zaɓin kayan abu: Zaɓin kayan yana taka muhimmiyar rawa a cikin hysteresis. Don haka, masana'antun a hankali suna zaɓar ainihin kayan aikin da ake amfani da su a cikin ginin firikwensin, kamar diaphragms, hatimi, da ruwa mai cike da ruwa, don tabbatar da sun nuna ƙaramin ƙaranci a ƙarƙashin yanayin aiki daban-daban.

- Haɓaka ƙira: Ta hanyar haɓaka ƙirar ƙirar firikwensin, kamar sura, girma, da kauri na diaphragms, da inganta hanyoyin rufewa, masana'antun na iya yadda ya kamata rage jijiyoyi da ke haifar da gogayya, juzu'i, da nakasar abu.

- Maganin tsufa: Sabbin na'urori masu auna firikwensin ƙera na iya nuna mahimmin ƙancewar farko. Ta hanyarmaganin tsufada takamaiman shirye-shiryen gwaji, kayan za'a iya haɓaka kayan aiki don daidaitawa da daidaitawa, don haka rage wannan ƙazamin farko. Hoton da ke ƙasa yana nunaXDB305jurewamaganin tsufa.

- Ƙuntataccen sarrafawa: Ta hanyar sarrafa juriya da inganci yayin aikin samarwa, masana'antun suna tabbatar da daidaiton kowane firikwensin kuma rage tasirin bambance-bambancen samarwa akan hysteresis.

- Ƙwararren ƙira da ramuwa: Wasu masana'antun suna amfani da fasahar ɗimbin ɗimbin ci gaba da hanyoyin daidaita ma'auni da yawa don ƙira daidai da gyara ƙugiya a cikin firikwensin firikwensin.

- Gwajin aiki da ƙididdigewa: Duk na'urori masu auna firikwensin suna yin cikakken gwaji don tantance halayen su. Dangane da sakamakon gwajin, ana ƙididdige na'urori masu auna firikwensin don tabbatar da cewa samfuran da suka cika ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ana fitar da su kasuwa.

- Gwargwadon gwajin rayuwa: Don tabbatar da kwanciyar hankali na na'urori masu auna firikwensin a duk tsawon rayuwarsu, masana'antun suna gudanar da saurin tsufa da gwaje-gwajen rayuwa akan samfuran don tabbatar da cewa ciwon ya kasance cikin iyakoki masu karɓuwa.

Waɗannan cikakkun matakan matakan suna taimaka wa masana'anta yadda ya kamata su sarrafa da kuma rage abin da ke faruwa na hysteresis a cikina'urori masu auna matsa lamba, tabbatar da cewa na'urori masu auna firikwensin sun haɗu da daidaitattun daidaito da buƙatun aminci a cikin ainihin aikace-aikacen.

Lokacin aikawa: Mayu-09-2024