Fahimtar Fasahar Fina-Finai

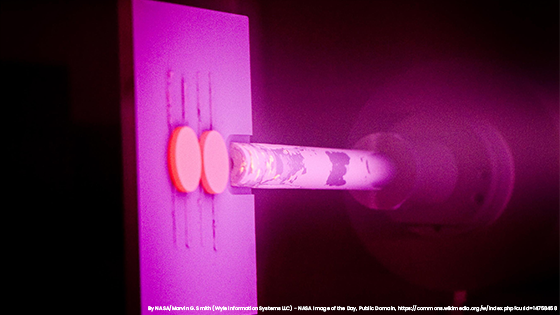

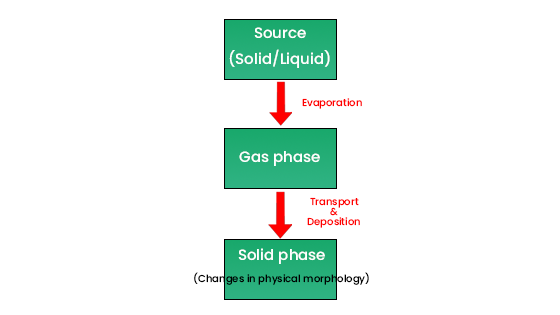

Fasahar fina-finai ta ƙunshe da ajiye kayan yadudduka na fata (yawanci daga ƴan nanometers zuwa ƴan mitoci kaɗan) a kan madauri. Ana iya yin waɗannan yadudduka da ƙarfe, semiconductor, insulators, ko wasu kayan, kuma ana amfani da su don ƙirƙirar kayan aikin lantarki. Wannan fasaha tana da mahimmanci musamman wajen kera na'urorin lantarki saboda tana ba da damar yin daidaici da aikin abubuwan haɗin gwiwa. Jigon fim na bakin ciki yawanci ana yin ta ta hanyar shigar da tururi ta jiki (PVD) ko ajiyar tururin sinadarai (CVD), yana tabbatar da inganci da aikin samfurin ƙarshe.

Haɓaka fasahar fina-finai na sirara ta samo asali ne tun tsakiyar ƙarni na 20 lokacin da aka sami ci gaba mai mahimmanci a kimiyyar kayan aiki da dabarun saka idanu. Da farko, an fi amfani da fasahar sirara-fim a masana'antar semiconductor don kera transistor da haɗaɗɗun da'irori. Yayin da fasaha ta ci gaba da karuwa da buƙata, kewayon aikace-aikacen fasahar fim na bakin ciki ya faɗaɗa cikin sauri. A yau, ana amfani da shi sosai a masana'antar firikwensin, kayan kwalliyar gani, sel na hasken rana, faifan diski mai ƙarfi, da murfin lalata, da sauransu. Misali, a masana'antar firikwensin, ana amfani da fasahar fim na bakin ciki don samar da na'urori masu auna matsa lamba, na'urori masu auna iskar gas, da na'urori masu auna zafin jiki, waɗanda ke da girman hankali da daidaito. Bugu da ƙari, aikace-aikacen fasahar fim na bakin ciki a cikin tsarin microelectromechanical (MEMS) da nanotechnology suma suna haɓaka, suna ba da tallafi mai mahimmanci don ƙirƙira da haɓakawa a waɗannan fagagen.

Mahimman siffofi na fasaha na sirara-fim sun haɗa da ainihin madaidaicin sa, sassauci, da damar haɗin kai da yawa. Babban madaidaici yana ba da damar fasahar fim na bakin ciki don cimma ingantacciyar ma'auni a cikin ƙaramin girman girman, wanda ke da mahimmanci ga na'urori kamar na'urori masu auna matsa lamba waɗanda ke buƙatar kiyaye ingantattun ma'aunin matsa lamba a ƙarƙashin yanayi daban-daban na muhalli. Sauƙaƙe na fina-finai na bakin ciki yana ba su damar daidaitawa da nau'ikan kayan aiki da buƙatun aikace-aikacen, ba da damar sanyawa akan nau'ikan abubuwa daban-daban kamar silicon, gilashi, ƙarfe, da robobi, don haka samun ayyuka da yawa. Bugu da ƙari, ana iya haɗa fasahar fim na bakin ciki tare da wasu fasaha da kayan aiki don ƙirƙirar na'urori masu haɗaka tare da ayyuka masu yawa. Misali, haɗa fasahar fim na bakin ciki tare da MEMS na iya samar da ƙananan na'urori masu auna matsa lamba waɗanda ba ƙanana da nauyi ba amma har ma masu hankali da dogaro.

Hakanan fasahar fim ɗin na iya haɗa ayyuka da yawa cikin na'ura guda ɗaya, ma'ana ana iya samun ji, aunawa, da sarrafa bayanai lokaci guda a cikin siraran fim, sauƙaƙe ƙira da tsarin kera na'urar. Wannan damar haɗin kai ba kawai yana haɓaka aikin na'urar da aminci ba amma har ma yana rage farashin masana'anta da rikitarwa. A cikin haɓaka na'urori masu auna matsa lamba, fasahar fim ɗin sirara na iya haɓaka aikin firikwensin sosai, ba su damar yin aiki da ƙarfi a wurare daban-daban masu rikitarwa.

Haɗin Fasahar Fina-Finan Sihiri a cikin Matsalolin Matsakaicin

Haɗin fasahar fim na bakin ciki a cikin firikwensin matsa lamba yana nufin haɓaka aiki, rage girman, da haɓaka hankali. Ta daidai sarrafa kaddarorin kayan abu da kauri mai kauri, fasahar fim na sirara tana sa haɓaka na'urori masu auna madaidaici mai yiwuwa. Wannan haɗin kai ba kawai yana inganta aikin na'urori masu auna firikwensin ba kawai amma kuma yana kawo fa'idodi masu mahimmanci a fannoni da yawa.

Da fari dai, fasahar sirara-fim tana ba da damar rage yawan firikwensin. Na'urori masu auna matsa lamba na al'ada galibi suna fuskantar gazawa a girman da nauyi, yayin da fasahar fim na sirara ke ba da izinin kera ƙananan firikwensin firikwensin haske ba tare da lalata aikin ba. Wannan yana da mahimmanci musamman ga aikace-aikace masu iyakacin sarari ko buƙatar mafita masu nauyi, kamar na'urorin likitanci da MEMS.

Na biyu, na'urori masu auna siraran fim sun yi fice wajen haɓaka hankali. Fasahar fim na bakin ciki na iya gano sauye-sauyen matsa lamba na mintuna tare da madaidaicin madaidaici, yana sa waɗannan na'urori masu auna firikwensin fa'ida a cikin mahallin da ke buƙatar ingantattun ma'auni. Misali, a cikin sarrafa kansa na masana'antu da sa ido kan muhalli, firikwensin matsa lamba na sirara na iya samar da cikakkun bayanai, don haka inganta ingantaccen tsarin gabaɗaya da aminci.

Bugu da ƙari, fasahar fim na bakin ciki na inganta aminci da dorewa na na'urori masu auna matsi. Babban daidaituwa da kwanciyar hankali na yadudduka na fim na bakin ciki suna tabbatar da daidaiton aiki akan amfani na dogon lokaci. Idan aka kwatanta da na'urori masu auna firikwensin gargajiya, na'urori masu auna fim na bakin ciki na iya kula da kyakkyawan aiki ko da a cikin matsanancin yanayi na muhalli, yana sa su zama masu amfani sosai a fannoni kamar sararin samaniya da masana'antar kera motoci.

Idan aka kwatanta da hanyoyin gargajiya, fasahar sirara-fim tana ba da madaidaicin nauyi, ƙarami, da kuma madaidaicin matsayi. Na'urori masu auna matsa lamba na al'ada galibi suna fuskantar ƙalubale cikin girma, nauyi, da daidaito, yayin da fasahar fim ɗin sirara, tare da mafi kyawun kayan aikinta da hanyoyin masana'anta, suna shawo kan waɗannan iyakoki. Na'urori masu auna siraran fim ba wai kawai suna da fa'ida cikin girma da nauyi ba amma kuma suna da fifikon firikwensin na'urar firikwensin gargajiya dangane da daidaito da azanci. Waɗannan fa'idodin sun sa fasahar fim ɗin sirara ta zama muhimmin ɓangare na haɓaka fasahar firikwensin zamani.

Kayayyakin don Fim ɗin Matsi na Matsalolin Fim

Zaɓin kayan don firikwensin matsa lamba na bakin ciki-fim yana da mahimmanci yayin da waɗannan kayan ke tasiri kai tsaye aiki da amincin na'urori masu auna firikwensin.

Kayayyakin gama gari

Abubuwan gama gari da ake amfani da su a cikin firikwensin matsa lamba na bakin ciki sun haɗa da karafa kamar zinari, platinum, da aluminium, waɗanda aka sansu da kyakkyawan halayensu da juriya na lalata. Zinariya, azaman abu mai ɗaukar nauyi, ana yawan amfani dashi a cikin sassan lantarki na firikwensin don tabbatar da daidaito da kwanciyar hankali na watsa sigina. Platinum, saboda kyakkyawan kwanciyar hankali na thermal da juriya na iskar oxygen, ana amfani dashi sosai a cikin na'urori masu auna sigina don yanayin yanayin zafi mai zafi. Aluminum, kasancewa mara nauyi kuma yana da kyakykyawan aiki, yawanci ana amfani dashi a aikace-aikacen firikwensin da ke buƙatar sarrafa nauyi. Bugu da ƙari, kayan semiconductor kamar silicon da germanium ana amfani da su sosai a cikin firikwensin matsa lamba na fim saboda kyawawan kaddarorin injin su da azanci, suna taka muhimmiyar rawa a cikin MEMS.

Na gaba Materials

Tare da ci gaban fasaha, kayan haɓaka irin su nanocomposites da graphene suna samun ƙarin kulawa don aikace-aikacen su a cikin firikwensin matsa lamba na bakin ciki. Waɗannan kayan ana bincikar su sosai don kyawawan kaddarorinsu da yuwuwar haɓaka aikin firikwensin. Nanocomposites sun haɗu da fa'idodin kayan daban-daban, suna ba da ingantaccen ƙarfin injina da haɓakawa, wanda zai iya haɓaka haɓakar firikwensin hankali da karko. Graphene, tare da tsarin sa na zarra guda ɗaya da fitattun kayan lantarki, ana ɗaukar kyakkyawan zaɓi don kayan firikwensin gaba. Ba wai kawai yana da matsananci-high conductivity ba har ma yana nuna kyakkyawan ƙarfin inji da elasticity, yana nuna babban yuwuwar haɓaka na'urori masu auna matsa lamba.

Kayayyakin Kayayyaki

Zaɓin kayan don firikwensin matsa lamba na bakin ciki-fim ya dogara ne akan kayan lantarki, injina, da kayan zafi don tabbatar da ingantaccen aiki a ƙarƙashin yanayin aiki daban-daban. Misali, na'urori masu auna firikwensin da aka yi amfani da su a cikin yanayin zafi mai zafi suna buƙatar kayan aiki tare da kyakkyawan kwanciyar hankali na thermal da juriya na iskar shaka, yayin da aikace-aikacen da ke buƙatar haɓakar hankali suna la'akari da ƙarancin wutar lantarki da na'urorin elasticity na kayan. Ta hanyar yin la'akari sosai da waɗannan kaddarorin kayan, masu zanen kaya na iya zaɓar mafi dacewa kayan don takamaiman buƙatun aikace-aikacen, tabbatar da aminci da daidaiton na'urori masu auna firikwensin a wurare daban-daban masu rikitarwa.

La'akarin ƙira don Na'urar Matsalolin Fim na Sirara

Abubuwan ƙira don firikwensin matsa lamba na sirara-fim suna nufin tabbatar da aikin su, amincin su, da kwanciyar hankali a aikace-aikace daban-daban.

Tsarin Tsarin

Tsarin tsari na firikwensin matsa lamba na bakin ciki-fim dole ne ya tabbatar da kwanciyar hankali na inji da ƙarfi yayin kiyaye hankali da daidaito. Wannan yana buƙatar masu zanen kaya suyi la'akari ba kawai kayan jiki na fim din na bakin ciki ba amma har ma da nauyin inji da matsa lamba a cikin ainihin aikace-aikace. Ƙirar tsarin firikwensin ya kamata ya yi tsayayya da matsalolin injina iri-iri da sauye-sauyen muhalli yayin da yake riƙe da ingantaccen siginar fitarwa.

Hankali

Hankali shine maɓalli mai mahimmanci a cikin ƙirar na'urori masu auna matsa lamba, tasirin zaɓin kayan aiki, kauri mai kauri, da fasahar masana'anta. Babban na'urori masu auna firikwensin na iya gano canje-canjen matsa lamba na minti, mahimmanci don ma'auni daidai da aikace-aikacen sarrafawa. Zaɓin kayan abu yana tasiri kai tsaye hankalin firikwensin; abubuwa daban-daban suna da kaddarorin inji da na lantarki daban-daban, masu dacewa da buƙatun aikace-aikacen daban-daban. Har ila yau kaurin fim ɗin wani abu ne mai mahimmanci; mafi ƙarancin fim ɗin, mafi girman hankali, amma wannan na iya rage ƙarfin injina, yana buƙatar daidaito tsakanin hankali da ƙarfi.

Daidaito da Daidaitawa

Samun babban daidaito da daidaito a cikin firikwensin matsa lamba na bakin ciki-fim yana buƙatar ƙira a hankali da matakan masana'anta don tabbatar da amincin ma'auni da maimaitawa. Wannan ya haɗa da daidai sarrafa kauri da daidaituwa na fim ɗin bakin ciki, zaɓar abubuwan da suka dace, da haɓaka hanyoyin masana'antu. Duk wani ƙananan karkata a cikin tsarin masana'anta na iya rinjayar aikin firikwensin, yin ingantaccen kulawa da gwaji ya zama dole.

Halayen Aiki Lokacin Amsa

Na'urori masu auna firikwensin matsa lamba yawanci suna da saurin amsawa, mai mahimmanci don aikace-aikace masu ƙarfi waɗanda ke buƙatar saka idanu kan matsa lamba na ainihi. Lokacin amsawa cikin sauri yana tabbatar da cewa firikwensin na iya ɗaukar sauye-sauyen matsa lamba da sauri, yana ba da tallafin bayanai na lokaci-lokaci don aikace-aikace a fannoni kamar sarrafa kansa na masana'antu, na'urorin likitanci, da sararin samaniya.

Dorewa

Zaɓin kayan da suka dace da kuma ɗaukar ingantattun dabarun masana'antu suna haɓaka dorewa na firikwensin matsa lamba na bakin ciki, yana tabbatar da dogaro na dogon lokaci. Dorewa yana da mahimmanci don aiki na dogon lokaci na na'urori masu auna firikwensin, musamman ma waɗanda ke aiki a cikin matsananciyar yanayi, kamar yanayin zafi mai zafi, zafi mai zafi, ko kuma gurɓataccen muhalli.

Zaman Lafiyar Muhalli

Na'urori masu auna firikwensin bakin ciki dole ne su kula da daidaiton aiki a ƙarƙashin yanayi daban-daban na muhalli, gami da sauyin yanayi, zafi, da damuwa na inji. Wannan yana buƙatar na'urori masu auna firikwensin don samun kwanciyar hankali mai kyau na muhalli, su kasance masu iya aiki a cikin kewayon zafin jiki mai faɗi, kuma su kasance masu rashin hankali ga canje-canje a cikin zafi da damuwa na inji. Zaɓin kayan aiki da ƙirar marufi suna taka muhimmiyar rawa wajen tabbatar da zaman lafiyar muhalli na firikwensin.

Aikace-aikace na Na'urar Matsalolin Matsalolin Fim na Baƙaƙe

A cikin masana'antar kera motoci, ana amfani da na'urori masu auna fim na bakin ciki a cikin tsarin kula da matsa lamba na taya (TPMS) don samar da bayanan matsa lamba na ainihin lokacin, haɓaka aminci da aiki. A cikin tsarin sarrafa injin, waɗannan na'urori masu auna firikwensin suna lura da mai da matsa lamba na iska, suna tabbatar da ingantaccen aikin injin da inganci. Bugu da ƙari, tsarin aminci na kera motoci kamar jakunkunan iska da tsarin birki sun dogara da firikwensin matsa lamba na sirara don madaidaicin matsi da kunnawa akan lokaci.

A cikin fannin likitanci, ana amfani da na'urori masu auna firam na bakin ciki a cikin masu lura da hawan jini, suna samar da ma'auni masu mahimmanci da marasa lalacewa masu mahimmanci don kulawa da haƙuri da ganewar asali. Hakanan ana amfani da su a cikin na'urori masu auna firikwensin don ci gaba da lura da ilimin halittar jiki, haɓaka sakamakon jiyya na haƙuri. Na'urorin likitanci masu sawa, kamar masu sa ido na motsa jiki da masu lura da lafiya, suna amfani da waɗannan na'urori don bin mahimman alamu da ayyukan jiki.

A cikin sashin sararin samaniya, ana amfani da firikwensin matsa lamba na bakin ciki don saka idanu kan matsa lamba na gida, tabbatar da mafi kyawun matsa lamba na gida don jin daɗin fasinja da aminci. Hakanan ana amfani da su don kula da lafiyar tsarin tsarin, masu iya gano abubuwan da zasu iya faruwa kafin su yi tsanani. Bugu da ƙari, waɗannan na'urori masu auna firikwensin suna da mahimmanci a tsarin kula da muhalli na jirgin sama, yana tabbatar da kwanciyar hankali ga ma'aikatan jirgin da kayan aiki.

A cikin aikace-aikacen masana'antu, ana amfani da firikwensin matsa lamba na bakin ciki don sarrafa tsari daidai, yana tabbatar da aiki mafi kyau da inganci. Tsarin na'ura na robots sun dogara da waɗannan na'urori masu auna firikwensin don amsawa ta hankali da fahimtar matsa lamba, haɓaka aikinsu da iyawarsu. Tsarin amincin masana'antu kuma suna amfani da firikwensin matsa lamba na bakin ciki don ganowa da amsa canjin matsa lamba, hana haɗari da tabbatar da amincin ma'aikaci.

Tambayoyin da ake yawan yi

Menene babban fa'idodin na'urorin matsa lamba na sirara-fim?

Na'urar firikwensin matsa lamba na bakin ciki suna ba da hankali sosai, ƙaramin ƙarfi, da ingantaccen aminci, yana sa su dace don aikace-aikace daban-daban. Babban hankalinsu yana ba su damar gano canje-canjen matsin lamba na minti, ƙirar ƙira ta sa su dace da ƙayyadaddun aikace-aikacen sararin samaniya, kuma ingantaccen aminci yana tabbatar da kwanciyar hankali na dogon lokaci a cikin yanayi mara kyau.

Ta yaya matsi na sirara-fim ya bambanta da na'urori masu auna firikwensin gargajiya?

Na'urori masu auna sikirin fim ɗin sun fi daidai, ƙanƙanta, kuma gabaɗaya sun fi ɗorewa fiye da na'urorin firikwensin girma na gargajiya. Suna ba da ingantacciyar aiki a aikace-aikace masu buƙata, suna iya aiki tsakanin yanayin zafi da matsi mai faɗi, kuma suna da mafi girman hankali da saurin amsawa. Waɗannan halayen suna sa firikwensin fim ɗin firam ɗin ya yi fice a yawancin aikace-aikacen da ake buƙata.

Wadanne abubuwa ne aka fi amfani da su a cikin firikwensin matsa lamba na sirara?

Abubuwan gama gari sun haɗa da ƙarfe kamar zinariya da platinum, semiconductor kamar silicon, da kayan haɓaka kamar graphene. Zinariya da platinum ana amfani da su sosai don kyawawan halayensu da juriya na lalata a cikin firikwensin firikwensin. Ana amfani da Silicon a cikin fina-finai na bakin ciki na semiconductor saboda kyawawan kaddarorin injinsa da halayen lantarki, yayin da graphene ana ɗaukar kyakkyawan zaɓi don kayan firikwensin gaba saboda fitattun kayan lantarki da ƙarfin injin.

Wadanne masana'antu ne suka fi amfana daga na'urorin matsa lamba na sirara-fim?

Motoci, likitanci, sararin samaniya, na'urorin lantarki na mabukaci, da masana'antun sarrafa kansa na masana'antu suna amfana sosai daga firikwensin matsa lamba na bakin ciki. A cikin masana'antar kera motoci, ana amfani da waɗannan na'urori masu auna firikwensin don lura da matsa lamba na taya da sarrafa injin; a cikin filin kiwon lafiya, ana amfani da su don saka idanu da hawan jini da na'urori masu aunawa; a cikin sassan sararin samaniya, ana amfani da su don kula da matsa lamba na gida da kuma kula da lafiyar tsarin; a cikin kayan lantarki masu amfani, suna haɓaka ƙwarewar mai amfani na na'urori masu wayo; kuma a cikin sarrafa kansa na masana'antu, ana amfani da su don sarrafa tsari da na'urori masu amfani da na'ura.

Wadanne fasahohin masana'antu ne ake amfani da su don na'urorin matsa lamba na bakin ciki?

Dabarun gama gari sun haɗa da sputtering, sinadari tururi ajiya (CVD), tarawar tururi ta jiki (PVD), da jigon atomic Layer (ALD). Wadannan fasahohin na iya sarrafa daidaitattun kauri, daidaituwa, da abun da ke cikin fim ɗin bakin ciki, tabbatar da aikin firikwensin da aminci. Sputtering hanya ce da ake amfani da ita sosai ta jiki don samar da fina-finai na bakin karfe; CVD da fasaha na PVD ana amfani da su akai-akai don sakawa semiconductor da kayan insulating; ALD na iya sarrafa kaurin fina-finai na bakin ciki a matakin atomic, wanda ya dace da shirya fina-finai masu bakin ciki.

Magana:

1.Harin, M. (2001). "Kimiyyar Kayayyakin Fina-Finan Fim." Jaridar Ilimi.

Lokacin aikawa: Juni-28-2024